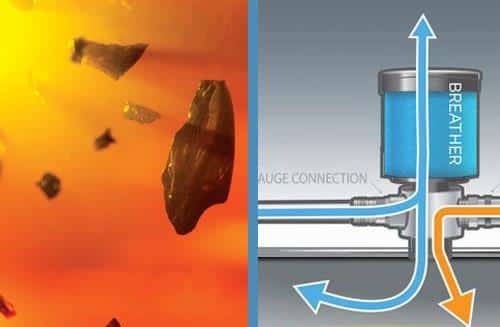

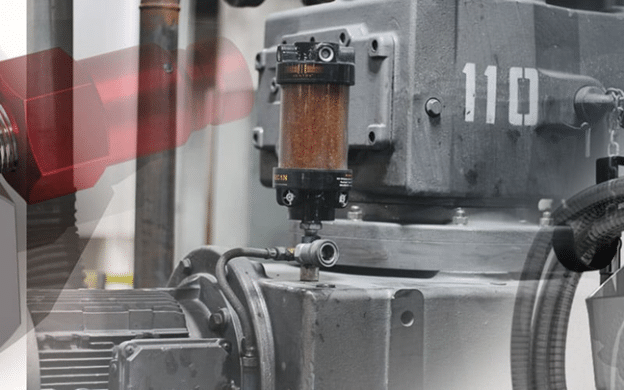

Many people are aware that lubricant contaminants cause wear in machines, but all too often that knowledge does not translate into action. It is surprisingly common for plants to go to great lengths in monitoring the condition of their equipment ...Continue Reading

Product Knowledge

Imagine you’re going about your daily work routine and you receive a call that a gearbox has just discharged oil everywhere. You go into reactive mode. You haven’t arrived on the scene yet to assess the extent of the situation, ...Continue Reading

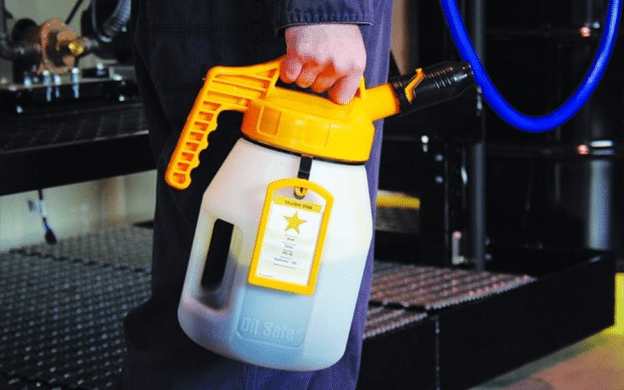

Many maintenance techs make considerable efforts to maintain the quality of their oil in storage, only to inadvertently compromise it during transfer to the machine through the use of unclean containers, pouring it through a contaminated funnel, or unintentionally mixing ...Continue Reading

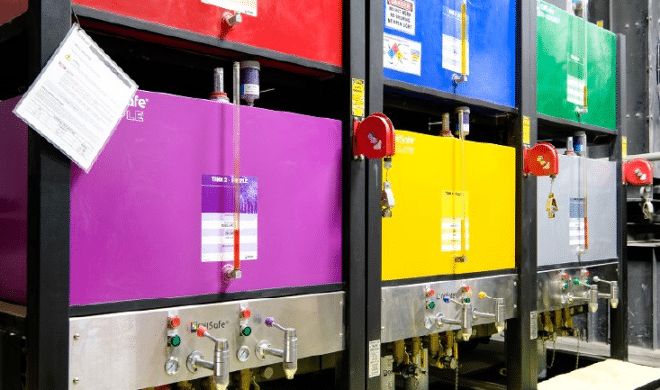

A comprehensive lubrication program is essential for maintaining machine reliability and maximizing equipment lifespan. Central to this is the proper storage and handling of lubricants in a dedicated lube room. However, convincing leadership to invest in lube room upgrades can ...Continue Reading

Knowing how to choose the right lubricants and apply them correctly is essential for equipment to operate smoothly. However, ensuring that lubricants remain contaminant-free in storage is equally important. Lubricant storage rooms play a pivotal role in maintaining the quality ...Continue Reading

Every day maintenance personnel in plants across North America fill or top off systems with new lubricants. Their intention is to positively impact the life and performance of the equipment. Yet, unknowingly they often add mixed, chemically-depleted lubricants containing particulate, ...Continue Reading