Desiccant breathers are an essential tool for protecting and prolonging the lifespan of industrial equipment. Here are 5 reasons why you should be using them.

- Protection against moisture: Desiccant breathers are designed to absorb moisture that may be present in the air, preventing it from entering equipment such as transformers and gearboxes. This can help to protect the equipment from rust and corrosion, prolonging its lifespan.

- Prevention of contamination: Moisture can also cause contamination of lubricants and other fluids in equipment, leading to decreased performance and increased wear and tear. Desiccant breathers can help to prevent this by removing moisture from the air before it enters the equipment.

- Improved performance: By removing moisture from the air and keeping equipment dry, desiccant breathers can help improve the equipment’s performance. This can include increasing the efficiency and longevity of the equipment and preventing breakdowns.

- Reduced maintenance costs: By preventing rust, corrosion, and contamination, desiccant breathers can help to reduce the need for maintenance and repairs. This can result in significant cost savings over the lifespan of the equipment.

- Versatility: Desiccant breathers are versatile and can be used in various industries and applications, including power generation, oil and gas, chemical and petrochemical, food and beverage, and many more.

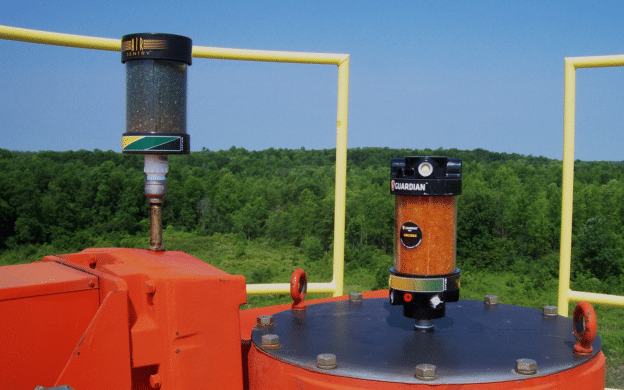

Air Sentry Breathers are designed to protect equipment from moisture, dust, and other contaminants by absorbing and removing them from the air before they enter the equipment. The Air Sentry Breathers utilize a two-stage filtration system, which includes a primary filter that removes larger particles and a desiccant bed that removes moisture. The desiccant bed is made of silica gel and can be recharged or replaced to maintain effectiveness. The Air Sentry Breathers are suitable for various applications, including power generation, oil and gas, chemical and petrochemical, food and beverage, and many more. They are available in different sizes and configurations to suit different requirements and environments.