Chances are, if you work in an industrial setting, you have someplace where you store lubricants. It might be an old shipping container, a sectioned-off part of a warehouse or even a collection of pallets outside and a few lockers. ...Continue Reading

OilSafe | Air Sentry News & Insights

Winners of the 2024 Lube Room Challenge: Brent Harmon, Clint Rieke, Kyle Shaffer, and Robert Hiss For the first time since 2019, Noria revived its annual Lube Room Challenge Competition, sponsored by OilSafe. Machinery Lubrication reached out and asked readers to ...Continue Reading

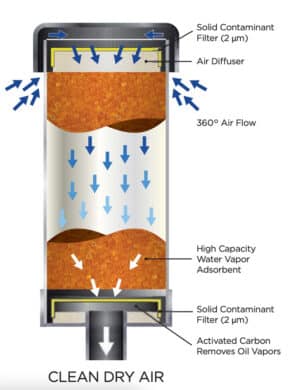

Air Sentry® Breathers replace existing breather caps or air vents on fluid holding storage tanks, hydraulics reservoirs and gearboxes. Most older style air venting methods provide minimal if any contamination control. Air Sentry® Breathers provide the first line of defense ...Continue Reading

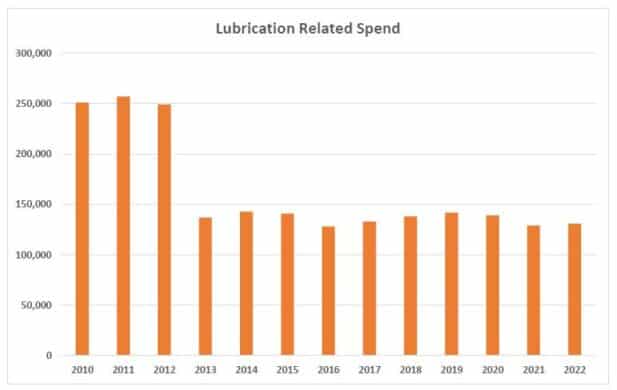

In 2011 a small box manufacturing plant in the United States looked to cut their unscheduled downtime and lubricant usage in the plant. They were chosen to be a beta site by their company to begin the journey to First ...Continue Reading

A lube room is often a dark, dirty, forgotten area inside a plant. However, it shouldn’t be this way, especially considering how important it is in keeping machines moving. After all, without proper lubrication, equipment would not rotate. By giving ...Continue Reading

Ensuring the optimal performance and durability of machines hinges on the critical aspect of controlling lubricant contamination. From the moment of lubricant reception through storage, transfer, and application, implementing effective measures to control contamination is essential. These measures help to ...Continue Reading