Keeping possible contamination sources away from lubricated equipment is the best line of defense against contaminants entering machine parts. It is significantly more difficult and expensive to remove contaminants from the system than it is to modify and protect equipment against ...Continue Reading

OilSafe | Air Sentry News & Insights

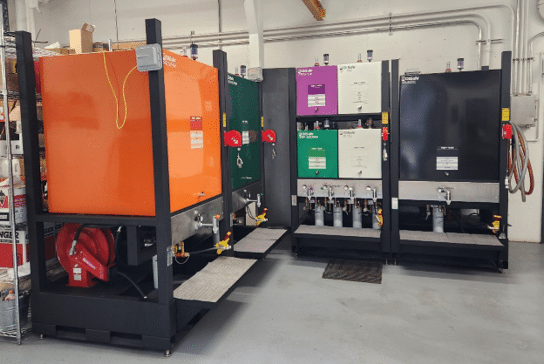

Your lube room is the foundation of your lubrication program and a key driver of equipment reliability. In this webinar, see how Georgia-Pacific’s Toledo plant turned an inefficient space into a best-in-class lube room. Then, OilSafe’s Dean Hammes will walk ...Continue Reading

Lubricants are essential for the smooth and efficient operation of many types of machinery, from engines and turbines to gears and bearings. However, lubricants can also be vulnerable to contamination from various sources, such as dirt, dust, water, metal particles, ...Continue Reading

When the reliability team at Georgia-Pacific’s paper mill in Toledo, Oregon, looked at their lube room just a few years ago, they saw more than just a cramped, cluttered space—they saw an opportunity. Now, after a complete overhaul grounded in ...Continue Reading

In the world of maintenance, reliability, and machinery lubrication, contamination control is not just a best practice — it’s a necessity. As industrial equipment becomes more sophisticated and expectations for uptime increase, the role of contamination control in ensuring long-term ...Continue Reading

One of the greatest opportunities I have as a technical consultant is the chance to walk through various plants around the world. I have visited power plants, food-processing plants, refineries, manufacturing facilities and a long list of others. During these ...Continue Reading