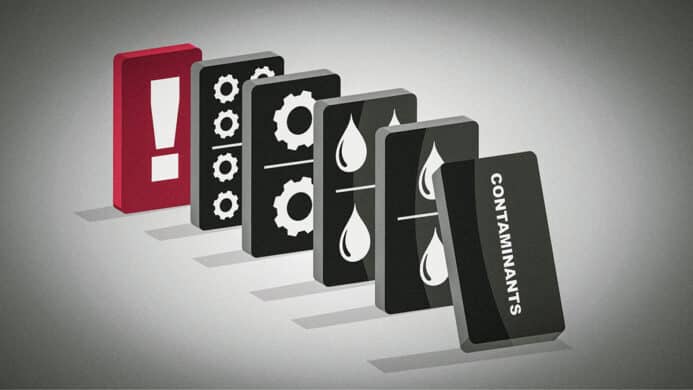

Keeping possible contamination sources away from lubricated equipment is the best line of defense against contaminants entering machine parts. It is significantly more difficult and expensive to remove contaminants from the system than it is to modify and protect equipment against ...Continue Reading

Published Articles

In the world of maintenance, reliability, and machinery lubrication, contamination control is not just a best practice — it’s a necessity. As industrial equipment becomes more sophisticated and expectations for uptime increase, the role of contamination control in ensuring long-term ...Continue Reading

One of the greatest opportunities I have as a technical consultant is the chance to walk through various plants around the world. I have visited power plants, food-processing plants, refineries, manufacturing facilities and a long list of others. During these ...Continue Reading

For a complete and proper lubrication program to work effectively and provide the most return on investment, every step must be considered, from receiving to application. Throughout the way, there are missed opportunities to increase equipment productivity and reliability and ...Continue Reading

These best practices can help your assets perform at peak efficiency. For many companies, lubrication is a required maintenance function that is too often considered a necessary evil or underestimated as a simplistic process. A deep, detailed look at your ...Continue Reading

One of the best ways to care for machine assets is to ensure that the lubricants protecting them are clean, healthy, and ready to perform before they are put into service in our machines. It is common for oil analysis to be ...Continue Reading