How many articles have you read, or seminars listened to, that tout the value of contamination control? If you are like me, they number in the hundreds—if not thousands. One thing about these articles and seminars that bothers me is ...Continue Reading

OilSafe

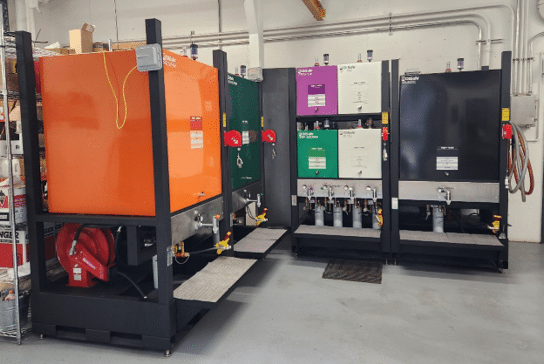

Your lube room is the foundation of your lubrication program and a key driver of equipment reliability. In this webinar, see how Georgia-Pacific’s Toledo plant turned an inefficient space into a best-in-class lube room. Then, OilSafe’s Dean Hammes will walk ...Continue Reading

When the reliability team at Georgia-Pacific’s paper mill in Toledo, Oregon, looked at their lube room just a few years ago, they saw more than just a cramped, cluttered space—they saw an opportunity. Now, after a complete overhaul grounded in ...Continue Reading

In the world of maintenance, reliability, and machinery lubrication, contamination control is not just a best practice — it’s a necessity. As industrial equipment becomes more sophisticated and expectations for uptime increase, the role of contamination control in ensuring long-term ...Continue Reading

One of the greatest opportunities I have as a technical consultant is the chance to walk through various plants around the world. I have visited power plants, food-processing plants, refineries, manufacturing facilities and a long list of others. During these ...Continue Reading

For a complete and proper lubrication program to work effectively and provide the most return on investment, every step must be considered, from receiving to application. Throughout the way, there are missed opportunities to increase equipment productivity and reliability and ...Continue Reading